Taking a look at recent history, there is no doubt that technology has fundamentally changed the business landscape. The steam engine in the 18th century fueled the Industrial Revolution. The introduction of the train in the 19th century brought rapid transportation to the world. That was followed in the 20th century with breakthroughs such as the airplane, the transistor, the microchip, and the internet. And in the 21st century, the big trend is digitization.

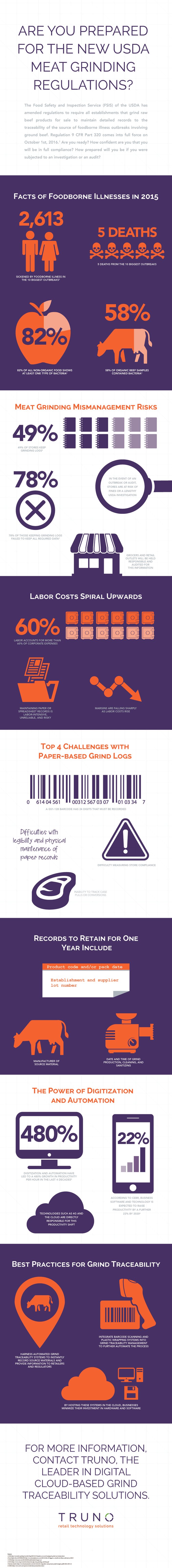

According to the Center for Economics and Business Research (CEBR), digitization and automation have led to 480% growth in productivity per hour in the last 4 decades. CEBR predicts that business software and technologies such as digitization, 4G, and the cloud are expected to raise productivity by a further 22% by 2020.

The meat grinding management field in particular has recently become the beneficiary of digitalization. A new wave of digital, cloud-based grind traceability solutions have entered the market to ease the process of record keeping within meat departments.

New Regulations in Force

The appearance of this technology is particularly timely in light of new USDA regulations impacting meat departments. The Food Safety and Inspection Service (FSIS) unit of the USDA has begun enforcing regulation 9 CFR Part 320 into full force since October 1st, 2016.

It requires all establishments that grind raw beef products for sale to maintain detailed records in an effort to improve the traceability of the source of foodborne illness outbreaks from ground beef. To help meat outlets comply with regulations relating to foodborne illness outbreaks, automated systems have been designed to take the risk and error out of grind traceability management.

Built around industry best practices, these systems instantly record source materials and provide all necessary information to retailers and regulators. The best systems come with integrated barcode scanning and plastic/Styrofoam wrapping systems to further automate meat delivery processes.

For example, store associates execute a simple point-and-click method to scan incoming source supply and the many other details required under the FSIS mandate using a handheld scanner. The system is fully aligned with daily in-store production activities. It can also run on existing scanners in the store. In the event of any foodborne illness outbreak, these systems help store management and regulators to rapidly and accurately identify potential source materials that could cause or contribute to reported illness.

Cloud Savings

Not everyone can afford the upfront costs for the hardware and software necessary to implement the latest digital technologies. By hosting grind traceability management solutions in the cloud, however, businesses can minimize their investment in hardware and software. Instead of large upfront costs, they operate on a subscription system, splitting costs into predictable monthly, quarterly, or annual payments.

Another benefit of the cloud is the speed of implementation. Instead of weeks or even months of laborious deployment of hardware, software, and middleware, cloud-based digital grind traceability management solutions can be implemented within a day or two.

For more information, contact TRUNO, the leader in digital cloud-based grind traceability solutions.