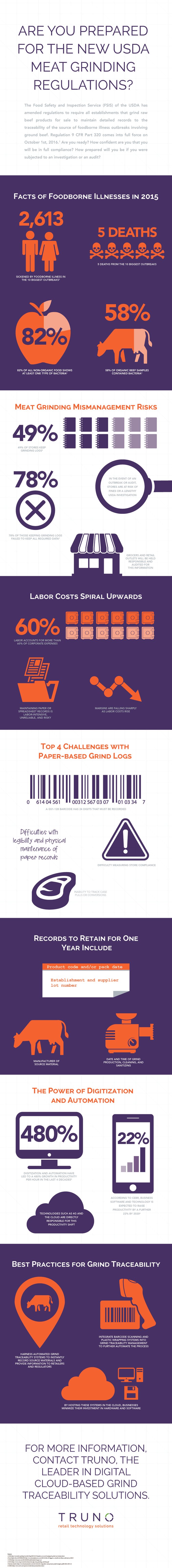

With big changes just implemented by the USDA’s Food Safety and Inspection Service (FSIS), meat counters around the country are scrambling. The FSIS is requiring all establishments that grind raw beef products for sale to maintain detailed records to the traceability of the source of foodborne illness outbreaks involving ground beef.

Unfortunately, most outlets are still not ready. The bulk of meat departments are struggling to comply. In the event of a foodborne illness outbreak, most are likely to fall short of possessing the necessary records in any subsequent investigation. And that opens the door to fines, PR flaps, or even closure, in extreme cases.

Time is Running Out

Regulation 9 CFR Part 320 went into full force on October 1st, 2016—and the rules are now being enforced. Those most in trouble are the 51% of stores that don’t keep any kind of grinding log, according to the Center for Disease Control (CDC). Some cases are so bad that 40% of those without a log don’t even know the purpose of having one, never mind the fact that they are required to keep one.

But even some companies that maintain logs are going to fall short. CDC surveys of hundreds of supermarkets and independent stores show that 78% of those keeping grinding logs failed to keep all required data. 26% omitted the establishment code of the source beef, 28% missed the grind data and time, and 41% failed to record the log number of the source beef.

Manual Log Failures

A big reason for these unhealthy statistics is the reliance on paper-based logs. The vast majority of current logs are kept up manually in a notebook by the meat counter. This approach requires personnel to copy lengthy barcode numbers and other required details. No wonder so many details are missing!

The new rules demand that all meat departments retain the following information for a period of one year:

- The date and time of grind production

- The date and time surfaces were cleaned and sanitized

- The manufacturer of source material

- The establishment and supplier lot number

- The product code and/or pack date

What are the chances of keeping all this data perfectly in a notebook beside the counter without error?

Turns out, it’s quite easy to omit or alter one or more of the 24 digits of a GS1-128 barcode, for example. But even in those rare cases when paper-based grind logs are up to date and accurate, there is the age old problem of legibility. Logs are likely to be written down by different personnel with quite a few unreadable scrawls among them. As customers pile up at the counter, record keeping and legibility are sure to decline. It’s likely that these written logs will have many missing records or even to drop out altogether.

In any case, with labor costs spiraling upwards, maintaining paper or spreadsheet records is labor-intensive, unreliable, and ultimately risky. Most stores see the advantage of digitizing manual processes, as they will minimize the man-hours spent on record keeping. This trend towards digitization is accelerating due to the fact that labor now accounts for more than 60% of corporate expenses.

The way to avoid such woes is to adopt an automated grind log solution. Truno’s Periscope Fresh-Trax system facilitates easy compliance with the newly imposed USDA recordkeeping regulations. For more information, about how your company can automate your log management and remain compliant, reach out to the experts at Truno to discuss your options.